The aim of this international standard ISO 19593-1, defined by the International Standards Organisation (ISO), is that any document intended to be printed, folded, cut, glued or laminated as a label or packaging should carry within itself everything necessary for it to be prepared to completion with the minimum intervention of human operators.

The publication of this standard intended to establish order and a common methodology in communications between designers and printing and packaging companies. Without this standard, each designer provides the instructions and materials to build a package as they see fit, forcing a manual intervention in which the recipient's judgement is often put to the test.

Defined in 2018, the full name of its first version is "ISO 19593-1:2018 Processing steps for packaging and labels".

In addition to cost and error savings, it allows optimised application of variable data and customisation of short runs with special inks or colours.

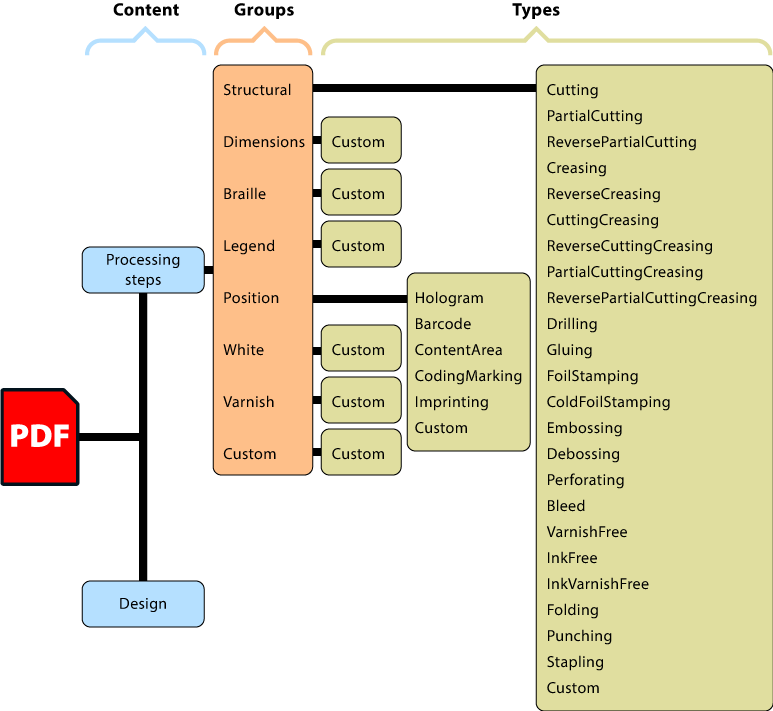

This standard defines how data must be marked in a PDF in order to clearly identify all steps in the processing of printed products for labels and packaging. This includes a number of obligations and prohibitions.

- Separation of the design from the processing steps: The main obligation is that printable design elements must be separated from non-design elements (the necessary indications for things like folding, creasing, varnish stains, etc.). However, just because an element is not part of the design, this does not mean that a machine will not make use of it (e.g. vector paths for a cutter or white ink flods for a design on dark material).

- Use of distinct layers and layer groups to separate processing steps: The second requirement is that each group of graphical elements that is part of the label or packaging creation process must be on its own PDF layer (optional content groups (OCG)).

Unambiguous identification in the metadata: The third obligation is that these layers must be identified with metadata that have a specific structure and syntax, i.e.: It is not simply a matter of creating layers and giving them names or metadata in any way. The metadata must be added or modified by a programme capable of recognising this standard and working with it (PitStop can do it, for example with the action "

Change layer processing steps - ISO 19593-1" in a list of actions).

In fact, a processing step layer is an Optional Content Group (OCG) that in its OCG dictionary has a key "

GTS_Metadata" where, in the form of another dictionary, the appropriate metadata are given with a very precise nomenclature, as seen in the picture above.Thus, each layer or group of layers has a corresponding "

GTS_Metadata" in the form of "GTS_ProcStepsGroup" and "GTS_ProcStepsType".The "

Name" of each layer is left to the choice of the users, who assign the names according to their preferences and needs (they are usually left unmodifieds but this is not obligatory).

Thus, the metadata identify the layers in a simple and unambiguous way so that they can be properly processed by any software prepared for this processing steps.

Setting a very specific structure: The fourth obligation is that the parts of the process are standardised into eight possible groups of layers, which can be further divided into types of elements, which in turn have their own layer.

The types can have a user-defined name, freely at the user's choice, except in two of the groups (Structural and Position), where there are several types with a fixed name.

It is not mandatory for a file does to have all groups or types in it. For groups that do not have default types, it is not necessary to establish a sublayer.

Admisible colours: Processing step elements that overlay design elements (e.g. cutting or folding marks) must be in a spot colour that overprints without transparency. The name of this colour can be any one but the reserved names (Cyan, Magenta, All, Black, etc.).

Elements that are not superimposed on the design can be in any colour or transparency mode.

The groups

As we have indicated, the objects of the process must each go on their own layer depending on which part of the process they belong to; for example: Elements defining dimensions and measures must all go on the same layer, while those indicating varnish areas must go together on another layer.

Each layer of the elements of the process must be identified in its metadata with a specific identification, which is detailed below (without translation). The "Name" of each layer can be the same as in the metadata or can be adapted to the convenience of each company or producer.

There are seven possible groups: Structural, Dimensions, Braille, Legend, Position, White and Varnish (plus an optional custom group that users can create if the others do not meet their needs):

- "

Structural": This group includes all objects that define the process steps a file must have. It is possibly the main group. - "

Dimensions": It must contain all the objects defining the measurements (indicative lines, texts, definition of the units of measurement, scale, etc.). - "

Braille": This group should include all the data related to Braille, for people with impaired or no vision. - "

Legend": All texts and elements describing the product and adding technical information should be included here, e.g. colour strips, patches identifying the use of colour samples and their names, registration marks or similar. - "

Position": This group contains all objects used to indicate where some elements go (barcodes, main content, etc.). - "

White": Here should go objects to be printed as a white ink flood to improve the reproduction of other objects when printing on difficult substrates (metallic, dark, transparent, etc.). - "

Varnish": Here got the objects that are printed with a varnish or similar. - "

Custom": This is where any processing steps that do not fit in with the above groups must go.

The types

Each group can have sub-layers. Most of them are custom, but there are two groups (Structural and Position), in which there are a number of "types" that must be identified with specific metadata:

Types of the Structural group

This group includes 23 default types and one custom:

- "

Cutting": This layer includes the paths or elements that indicate the internal or external lines that must cut the sustrate of the package or label. - "

PartialCutting": This layer is for the paths or elements that indicate partial cutting lines, i.e. that cut the substrate but not completely, leaving it ready to be separated with a slight pressure from the end user, e.g. kiss die cutting. - "

ReversePartialCutting": Here go the lines or elements that indicate partial reverse cut lines, i.e. that partially cut the material on the reverse side of the printed sheet. - "

Creasing": The crease marks for subsequent folding are placed on this layer. - "

ReverseCreasing": Here go the reverse crease marks, i.e. the ones on the opposite side to the one applied in the "Creasing" layer. - "

CuttingCreasing": In this layer go the elements which crease and cut the substrate discontinuously. - "

ReverseCuttingCreasing": In this layer we place the elements which crease and cut the substrate discontinuously on the opposite side to the previous "CuttingCreasing" one. - "

PartialCuttingCreasing": This layer must contain the paths or elements which crease and cut the substrate discontinuously and partially. - "

ReversePartialCuttingCreasing": This layer must contain the paths or elements which crease and cut the substrate discontinuously and partially on the opposite side to the previous "PartialCuttingCreasing" one. - "

Drilling": This layer must contain the elements that make a hole in the substrate with a specific size. - "

Gluing": In this layer should go those elements indicating areas of adhesive or glue application. - "

FoilStamping": This layer contains the elements to be applied as a foil by hot stamping. - "

ColdFoilStamping": This layer contains the elements to be applied with the cold foil stamping system. - "

Embossing": This layer contains the elements to be applied as an embossing die cut (high relief ). - "

Debossing": This layer contains the elements to be applied as an debossing die cut (bas-relief ). - "

Perforating": This layer is for those elements that will make a perforation of the substrate with dots or stripes. - "

Bleed": This layer includes the elements indicating the bleeding area. - "

VarnishFree": This layer indicates which areas of the document should be free of varnish. - "

InkFree": This layer indicates which areas of the document should be ink-free, i.e.: The areas not to be printed with any ink. - "

Folding": In this layer go the elements that indicate a folding without creasing. - "

Punching": Here are the elements that indicate a perforation for elements such as eyelets, clamps, brackets or the like - "

Stapling": This layer is used to mark the location of the staples.

Types of the group Position

This group includes five default types and one custom. These types are used to indicate the position in which common and often variable elements are to be placed on labels and packaging.

Warning: These layers include graphical elements (e.g. vector boxes) to indicate position, but do not include the referenced elements themselves.

- "

Hologram": This layer marks the position where a jologram should be placed. - "

Barcode": This type indicates the location of a barcode. - "

ContentArea": This layer indicates the boundaries that delimit the area where images or texts content relevant to the design can be placed safely. - "

CodingMarking": This layer is used to mark the area to place additional information (batch numbers, best-before/production dates, etc.). - "

Imprinting": This layer references the location of additional information, such as customer or company names which are usually variable data.. - "

Custom": This is where we place any processing step that do not fit in with the above.

The ISO 19593-1 processing steps and their metadata are compatible with those PDF standards that support the use of layers, e.g. PDF/X-4 and PDF/X-6.

[© Gustavo Sánchez Muñoz, 2025] Gustavo Sánchez Muñoz (also identified as Gusgsm) is the author of the content of this page. Its graphic and written content can be shared, copied and redistributed in whole or in part without the express permission of its author with the only condition that it cannot be used for directly commercial purposes (that is: It cannot be resold, but it can form part as reasonable quotations in commercial works) and the legal terms of any derivative works must be the same as those expressed in this statement. The citation of the source with reference to this site and its author is not mandatory, although it is always appreciated.